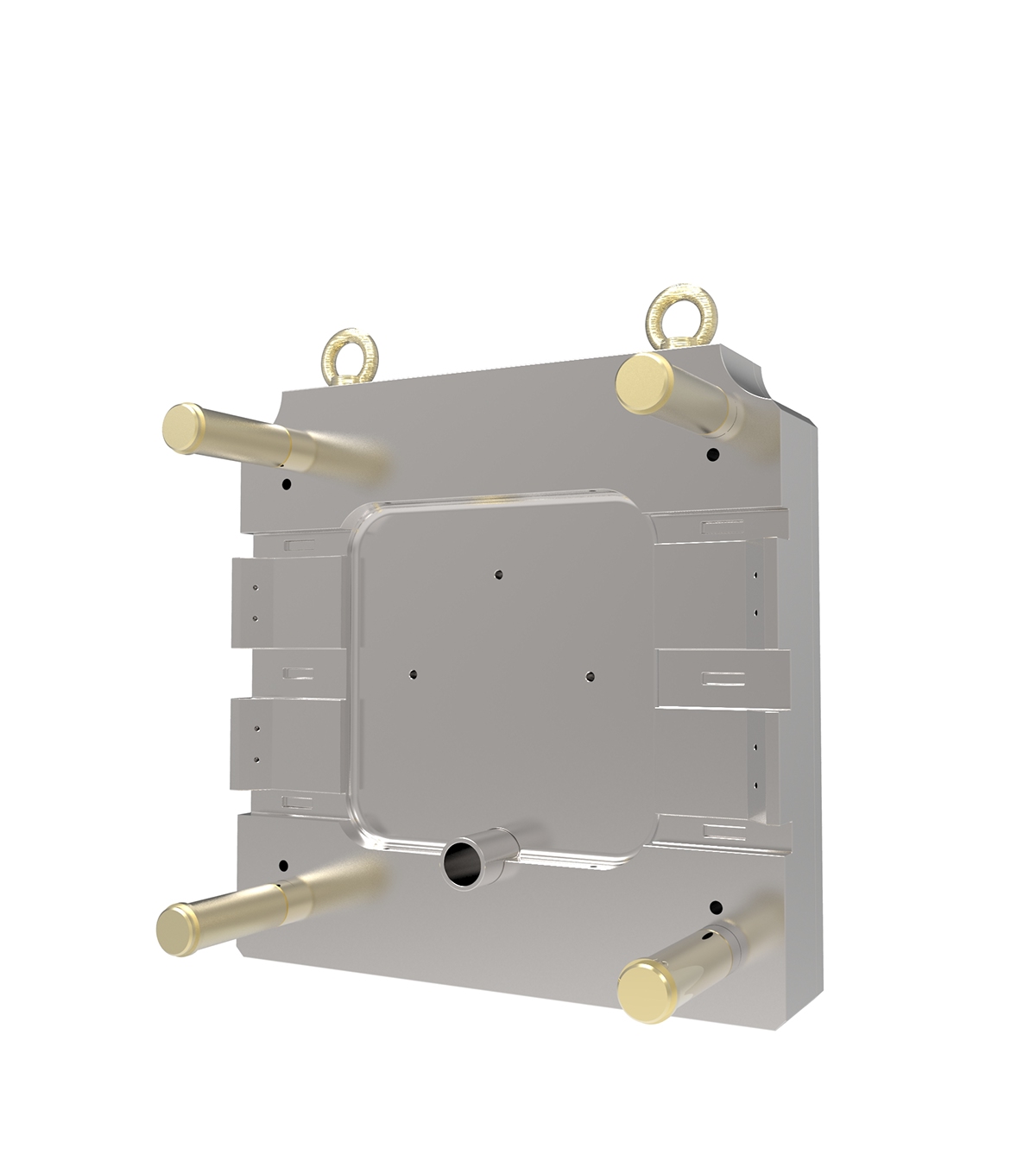

For the Design and Prototyping of Moulds and Dies subject we had to design an entire mould for a given piece, as well as redesign the piece so it could improve the production process and avoid faults. The result was more than 30 parts that had to be assembled and fitted perfectly with each other.

The mould was of 4 cavities and the supply channel had to be calculated so the filling of the four pieces was uniform and equal.

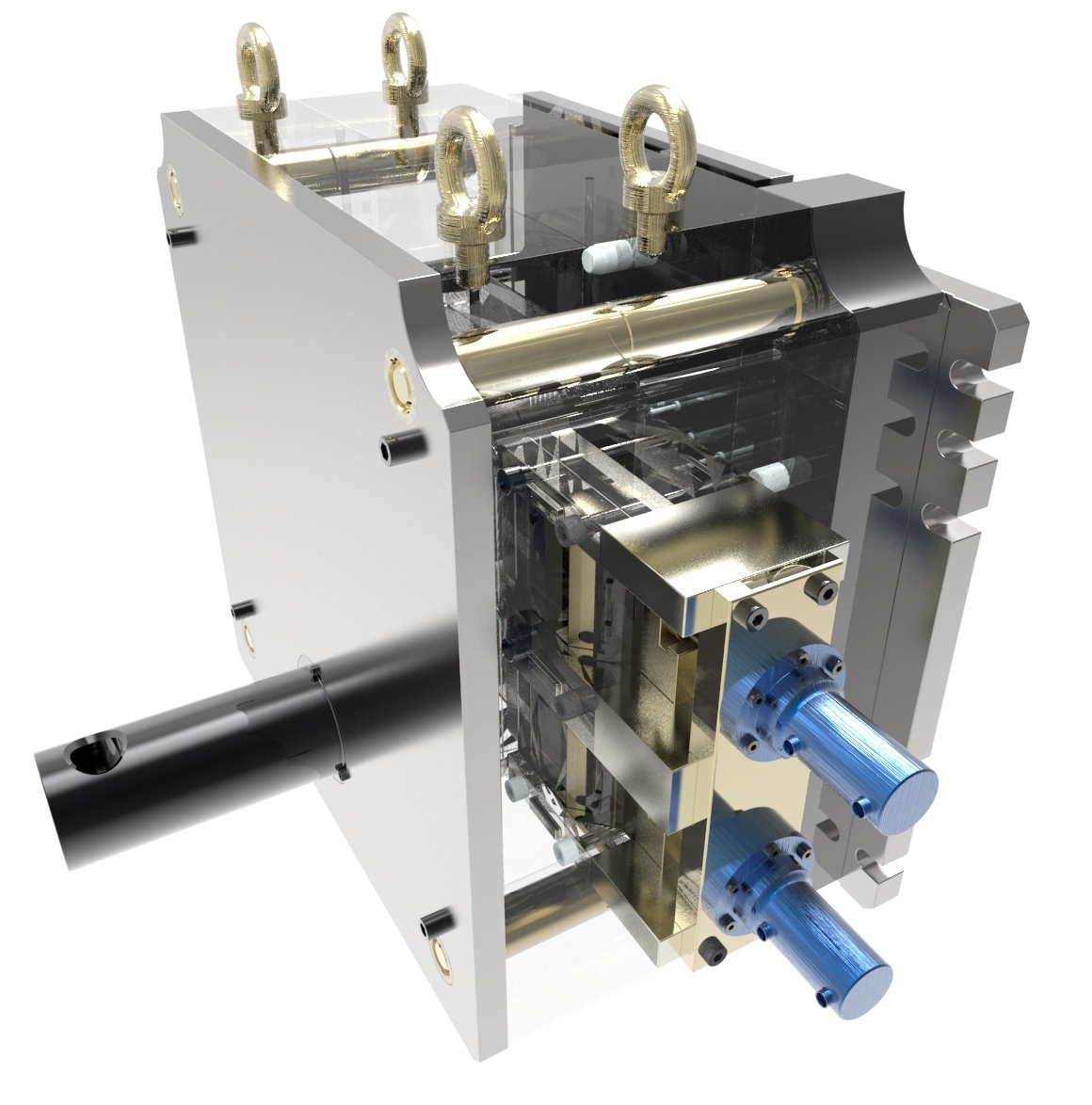

The ejectors can be seen in this image, these would allow the mobile part to move and extract the finished piece after the introduction of the melted material and cooling.

The whole set of sliders had to be designed from zero to be able to create the bottom of the piece with the desired dimensions and shape.